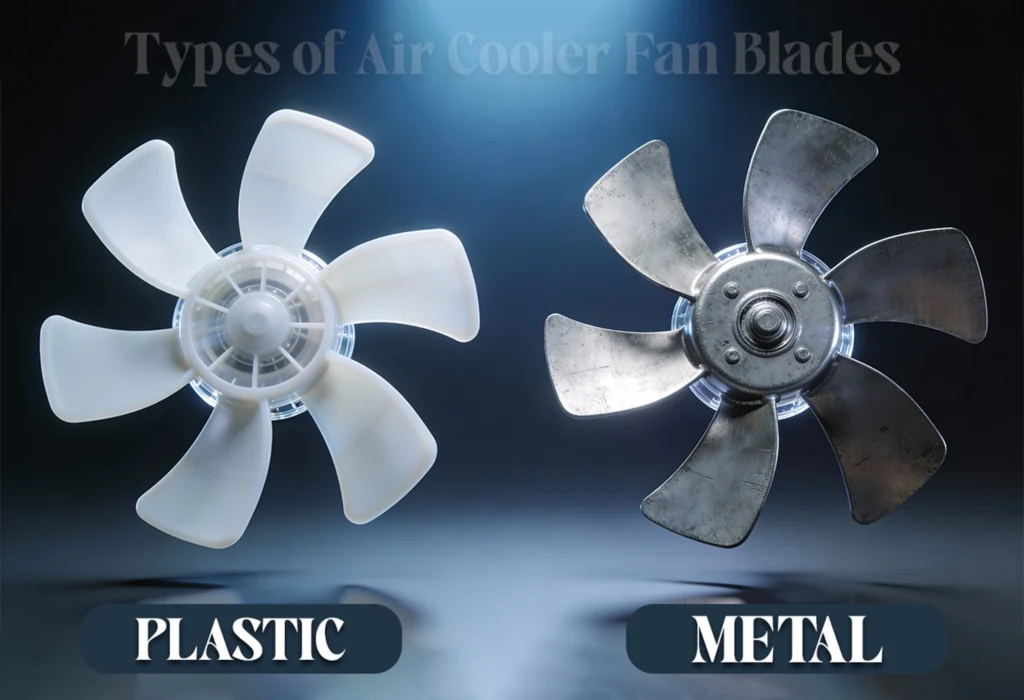

When choosing an air cooler, most buyers focus on factors like tank capacity, cooling pads, or airflow rating, while the fan blade material often goes unnoticed. However, fan blades play a critical role in determining how effectively an air cooler performs. The choice between plastic and metal fan blades directly affects airflow strength, noise levels, energy consumption, durability, and long-term reliability. Understanding this difference helps homeowners, dealers, and commercial buyers select an air cooler that truly matches their usage needs rather than relying only on surface features.

Why Fan Blade Material Matters in Air Coolers

Fan blade material influences how smoothly and efficiently air moves through the cooler. The weight and rigidity of the blade affect balance and vibration, which in turn impact noise levels and motor stress. Blade material also determines how well the fan maintains its shape at high speeds, how resistant it is to corrosion or wear, and how long it performs optimally. A well-matched fan blade material improves cooling efficiency, reduces maintenance issues, and extends the overall life of the air cooler.

What Are Plastic Fan Blades in Air Coolers?

Plastic fan blades are commonly made from materials such as ABS (Acrylonitrile Butadiene Styrene) or polypropylene. These materials are lightweight, corrosion-resistant, and easy to mold into aerodynamic shapes. Because of their low weight, plastic blades put less load on the motor, allowing quieter operation and lower power consumption. Plastic fan blades are typically used in personal coolers, tower coolers, and many domestic air coolers where moderate airflow, low noise, and energy efficiency are prioritized.

What Are Metal Fan Blades in Air Coolers?

Metal fan blades are usually manufactured from aluminum or coated steel. These blades are heavier and more rigid, which allows them to move larger volumes of air with greater force. Their strength makes them suitable for high-speed operation in demanding conditions. Metal fan blades are commonly found in desert coolers, window coolers, and commercial or industrial air coolers where strong airflow, long air throw, and durability under continuous operation are essential.

Plastic vs Metal Fan Blades – Working Difference Explained

The fundamental working difference between plastic and metal fan blades lies in their weight and stiffness. Plastic blades, being lighter and more flexible, rotate smoothly and quietly but are optimized for moderate airflow. Metal blades, due to their rigidity and mass, generate stronger airflow and maintain their shape even at high RPMs. This difference directly affects how air is pushed through cooling pads and distributed across the room.

Airflow & Cooling Performance Comparison

Metal fan blades generally deliver higher air volume and longer air throw, making them more effective in large rooms, halls, or open spaces. Plastic fan blades provide sufficient airflow for small to medium rooms but focus more on even distribution rather than distance. While both can cool effectively when used in the right application, metal blades are better suited for heavy-duty cooling, whereas plastic blades excel in controlled, indoor environments.

Noise Levels & User Comfort

Noise levels are a major consideration for home users. Plastic fan blades tend to operate more quietly because of their lighter weight and better balance, making them ideal for bedrooms, study rooms, and living areas. Metal fan blades can produce more noise and vibration, especially at high speeds, but this is generally acceptable in commercial, industrial, or outdoor environments where powerful airflow is more important than silent operation.

Energy Consumption & Motor Stress

Blade weight has a direct impact on motor load. Plastic fan blades, being lightweight, require less power to rotate, resulting in lower electricity consumption and reduced motor strain. Metal fan blades demand stronger motors to handle their weight and airflow output, which can increase power consumption. However, in large coolers, metal blades operate more efficiently because they move more air per rotation, balancing out energy usage when matched correctly with the motor.

Durability, Safety & Lifespan

Plastic fan blades are resistant to rust and corrosion, making them suitable for humid environments and long-term indoor use. However, they may crack or deform under extreme stress or impact. Metal fan blades are highly durable and resistant to physical damage, but they require proper coating to prevent rust over time. From a safety perspective, both types are safe when properly enclosed within a sturdy grill, but metal blades demand stricter safety standards due to their higher momentum.

Application-Based Suitability

For personal and tower coolers used in homes and apartments, plastic fan blades are generally the better choice due to quieter operation, energy efficiency, and adequate cooling performance. Desert and window coolers benefit from metal fan blades because they require high airflow and long air throw to cool larger spaces. Commercial and industrial coolers almost always rely on metal fan blades to handle continuous operation, heavy workloads, and demanding environmental conditions.

Which Fan Blade Is Better for You?

The right fan blade material depends on your specific needs. If you require quiet operation, low power consumption, and cooling for small to medium rooms, plastic fan blades are ideal. If your priority is strong airflow, wide coverage, and cooling for large or open spaces, metal fan blades offer better performance. Considering room size, usage duration, noise tolerance, and environment will help you choose the most suitable option.

Conclusion

Plastic and metal fan blades each serve a distinct purpose in air coolers. Plastic blades focus on efficiency, quiet operation, and comfort for domestic use, while metal blades emphasize power, durability, and performance for heavy-duty cooling. Understanding these differences enables buyers to make informed decisions and select air coolers that deliver the best balance of cooling efficiency, comfort, and long-term reliability.