Traditional air conditioners don’t work well for cooling large areas like production floors, warehouses, factories, or workshops. They’re pricy, power-hungry, and unsuitable for spaces with high ceilings or semi-open spaces. Industrial air coolers are useful for that. They are made to withstand the rigors of industrial operations and offer strong airflow, energy savings, and durability.

Choosing the best industrial air cooler for businesses is all about maintaining worker productivity, protecting equipment from heat, and reducing operational costs. Let’s explore the key features you should look for before making that investment.

Cooling Capacity and Airflow

The first and most crucial feature of any industrial air cooler is its cooling capacity, which directly depends on its airflow rate, usually measured in CFM (Cubic Feet per Minute). The higher the CFM, the more air the cooler can circulate, making it capable of handling large or open spaces efficiently.

For example, a small workshop may require a cooler with 5,000–8,000 CFM, while a large factory or warehouse may need one above 15,000–30,000 CFM. Choosing the right capacity ensures that every corner of the space gets uniform cooling. Undersizing the cooler will lead to inadequate performance, while oversizing can waste energy. Understanding your space volume, ceiling height, and ventilation layout is essential to picking the right model.

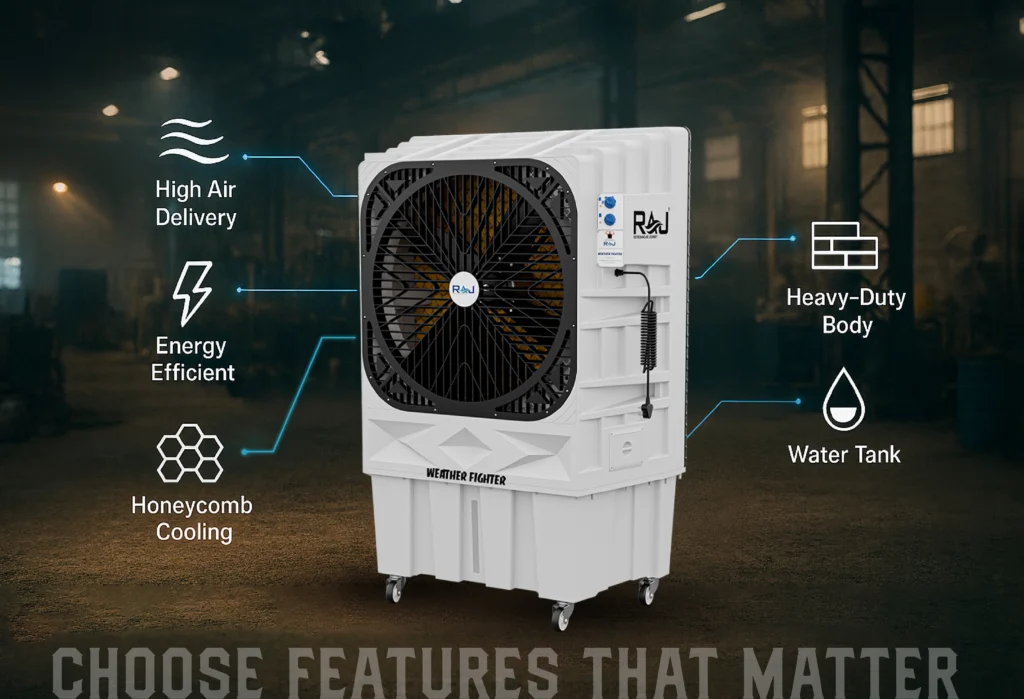

Durability and Material Quality

In the Industrial environment, durability matter as In the Industrial environment, durability matter The material quality of the air cooler determines how well it stands up to dust, vibration, and long working hours. Look for a metal body with powder coating that prevents corrosion and rusting, especially if your setup is near coastal or humid areas.

High-quality plastic or galvanized steel panels give coolers more durability and strength. Industrial-grade motors, strengthened fan blades, and stainless steel screws guarantee that your cooler will function even in the most demanding operating environments. Longer lifespans and lower maintenance costs are associated with stronger construction.

Energy Efficiency

Energy Efficiency is a matter in every business, as every business is trying to balance performance with cost savings. Industrial air coolers equipped with BLDC motors (Brushless Direct Current) or copper-wound motors offer significant improvements in power efficiency and operational reliability. These motors use less electricity while maintaining high airflow output, helping businesses save on long-term energy bills.

Compared to air conditioners, Industrial coolers run efficiently and consume

. Where air conditioners consume thousands of watts per hour, Industrial coolers consume only between 400 and 800 watts. the combination of low power usage and high cooling output makes air coolers one of the most cost-effective industrial cooling solutions available today.

Water Tank Capacity and Continuous Supply Options

Industrial air coolers cool down the air using the evaporating process, which means a continuous water supply is necessary for coolers. A large tank between 100 to 300 liters is ideal for continuous cooling for several hours. However direct Water connection is a better option for especially in factories or warehouses.

This configuration minimizes downtime and manual refilling efforts by automatically refilling the cooler. Industries that run continuous processes or multiple shifts will find it especially helpful. To guarantee dependable, seamless operation, look for features like water level indicators, overflow protection, and automated water distribution systems when assessing models.

Advanced Cooling Pads

The Cooling pads play a big role in deciding how fast an air cooler can cool down the temperature of your space. Modern air coolers mostly use either honeycomb pads or wood wool pads. Honeycomb pads are made from cellulose material, which is known for its longer life span, higher cooling efficiency, and low maintenance. Honeycomb pads allow optimal water retention while ensuring good air passage. however, although they may need to be replaced more frequently, wood wool pads are reasonably priced and offer superior cooling. For balanced performance and cost, you can select either type based on your usage and environment.

Noise Level and Maintenance Ease

Workplace comfort not only depends on temperature, it also on noise. A high-performance Industrial air cooler should run quietly even when delivering powerful airflow. Look for coolers with aerodynamically designed fan blades and balanced motors that minimize vibration and noise during operation.

Maintenance is also another crucial aspect. In an industrial setting, ease of access to components such as the motor, pads, and water tank can save hours of downtime. Features like removable cooling pads, drain outlets, and rust-free tanks simplify cleaning and upkeep, ensuring your cooling system remains efficient all year round.

Portability or Fixed Installation Options

Every Workspace has its own different needs. some spaces need a fixed, ducted cooling system, while others require portable air coolers that can be easily carried from one place to another. these types of industrial coolers, often fitted with heavy-duty wheels, are perfect for workshops, small factories, or event setups that need flexibility. on the other hand, fixed installation models are better suited for large manufacturing plants or warehouses, where uniform, centralized cooling is required. Choosing between the two depends on your operational setup and how often your cooling zones change.

Additional Smart Features

Today’s industrial cooling systems are getting smarter and more user-friendly. Many modern models come with remote control operation, variable fan speeds, digital temperature displays, and even IoT-enabled control systems that allow remote monitoring and automation.

These features make it easier to adjust cooling performance based on real-time temperature and humidity levels, optimizing both comfort and energy use. Some advanced models even include auto water refill systems, thermal protection for motors, and MCB safety features to prevent overload, ensuring seamless, safe, and efficient performance.

Conclusion

Choosing the right industrial air cooler goes beyond just picking a brand or model; it’s about finding a system that combines performance, efficiency, and durability to meet your business needs. The best units offer a perfect balance of strong airflow, robust build quality, energy-saving design, and easy maintenance. Investing in a well-built air cooler not only keeps your workspace comfortable but also protects machinery, improves worker productivity, and contributes to long-term cost savings. discover Raj Cooling Systems’ advanced range of industrial air coolers engineered for power, performance, and durability.